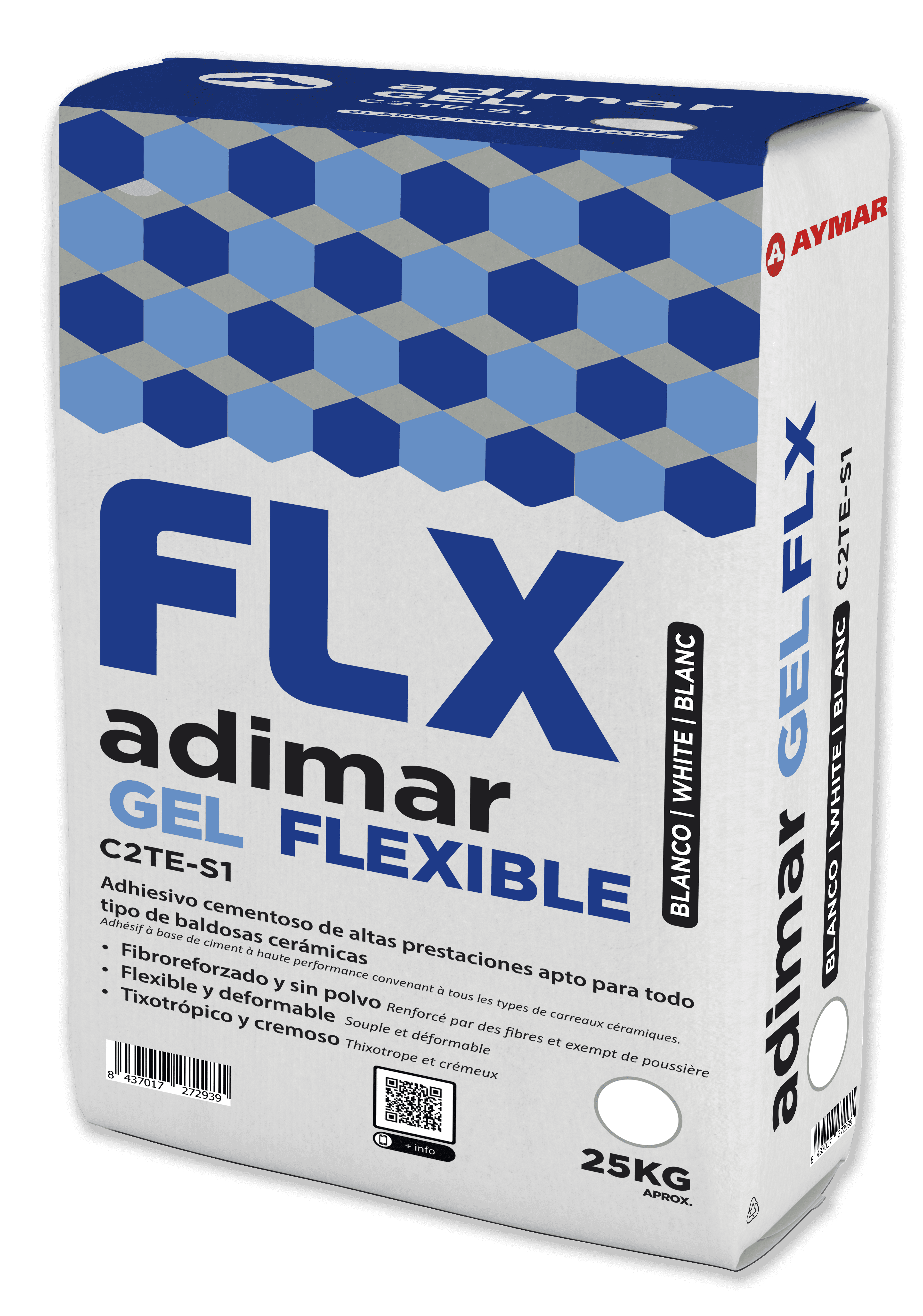

Adimar Gel Flexible

The Adimar Flexible Gel ceramic tile adhesive manufactured by AYMAR S.A.U. is an improved powder-free cementitious adhesive reinforced with polymeric fibres. It has a finer granulometry that allows for better distribution on the substrate. Depending on the mixing water, it has the capacity to have two types of consistency: gel consistency (creamy, light and thixotropic for vertical application) and fluid consistency (with greater smoothness and ease of application on horizontal substrates). It has reduced slip, prolonged open time and is deformable type C2TES1 in accordance with the UNE-EN 12004:2017 standard, designed with marble aggregates, cement and special additives that give it a high resistance to sagging and settling in pieces of large format or weight. In addition to adhesion, sliding and water retention suitable for laying ceramic tiles.

Made in Spain.

- Application field

- Instructions of use

- Recomendations of use

Adimar Gel Flexible has ideal characteristics for the installation of ceramic, marble, stone or similar small and large format pieces, absorbent or non-absorbent, on mortar render, concrete, large format brick, marble, terrazzo, prefabricated blocks, plaster, plasterboard, anhydrite, etc. In exterior applications (facade coatings, etc.) and interior (large surface pavements, etc.). Thanks to its flexibility, it is able to withstand thermal shocks and small differential movements produced by the substrate, making it suitable for radiant heating floors and applications on floors with heavy traffic, and is even suitable for immersion, e.g. swimming pools. Suitable for overlaying on old stoneware floor and wall tiles.

- Preparation of the substrate: The substrate on which the application is to be made must be resistant, dry, level, free of dust and free of any traces of release agent.

- Preparation of the mixture: add 7.75-8.25 l of water per bag and mix manually or mechanically, with a low speed electric mixer, to eliminate any possible presence of lumps in the paste, allow the mixture to stand for 5 min. and carry out a brief re-mixing.

- Application of the paste: Apply the product on the substrate using a notched trowel, to regularize the thickness, in a maximum extension of 2 m2, applying sufficient pressure so that the minimum contact with the cement is 80%. Place the tiles, pressing them until the grooves are flattened and the tiles are correctly set with the help of a rubber mallet. It is necessary to verify, with the fingertips, periodically that the adhesive has not formed a film on its surface, if this happens the product must be combed again taking into account that we are still in the margin of the open time of this (if the temporary strip since its application has exceeded the above mentioned open time the adhesive must be removed and reapplied).

- The application temperature must be between 5 °C and 35 °C on the substrate.

- Do not apply on substrates with residual humidity > 5%.

- Check the planimetry of the substrate with a 2 m ruler, verifying that the deviations must be less than 5 mm. If there are larger deviations, they must be regularised before application.

- Do not apply if frost is expected or in full sun.

- It is advisable to leave a minimum joint of 2 mm between tiles by applying ADIMAR UNIVERSAL JOINT 0/15 or TECHNICAL JOINT 0/16.

- Cold rooms must remain turned off until the adhesive curing is complete, a minimum of 7 days depending on the environmental conditions.

- In case of use in swimming pools, the pool can be refilled 7 days after application.

- For large format ceramics (the longest side of the tile > 1.5m) or for ceramic sheets (3.6mx1.5m) apply Adimar Superflex.

- For façade cladding:

- * leave a minimum joint of 5 mm by applying ADIMAR UNIVERSAL JOINT 0/15 or TECHNICAL JOINT 0/16 to it.

- * Make expansion joints every 30 m2 in large formats or every 60 m2 in small formats, as well as perimeter joints in cornices, overhangs and respect the structural joints of the building.

- * To prevent water from entering the bonding layer, which would favour detachment in the event of frost, protect the upper edges of the cladding with metal profiles, guttering, etc.

- * Do not apply to tiles with a high coefficient of expansion.

- * For sizes greater than 2400 cm2 or weights greater than 40 Kg/m2 it is essential to use mechanical anchors or safety staples and double gluing.

- *In ceramic overlaps, remove poorly adhered pieces and fill the gaps the day before application. Make sure that the ceramic tile is free of grease or wax, sanding it if necessary.

- On very absorbent substrates it is advisable to dampen it and wait until it is dry.

- Maximum recommended thickness: 10 mm.

- In applications on ceramic flooring, it is recommended to remove badly adhered pieces, sand the surface and double glue.

- Always double glue for large format pieces (> 1200cm2) or heavy weight and on substrates with radiant heating, which must be turned off 24 hours before application.

- On deformable substrates (plasterboard), check the rigidity of the partition and that the residual humidity is < 3%. If the substrate is weak, apply a surface hardening treatment by means of a primer.

- Do not apply on dead plaster that has received a thin layer of final plaster.